21+Experience

21+Experience

Research and Design

Research and Design

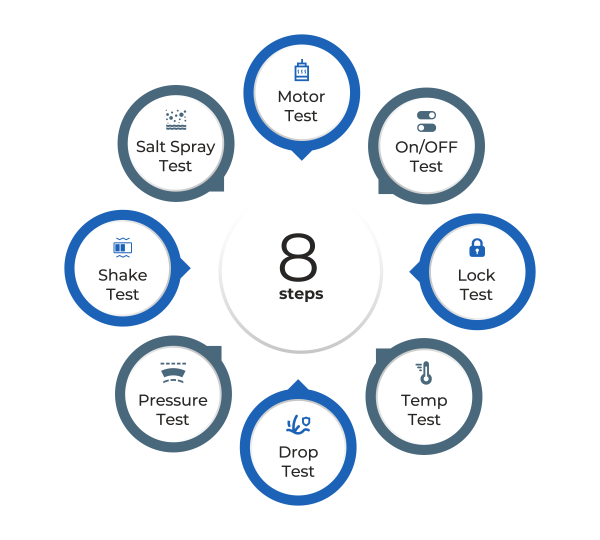

With a professional engineering team rich in design and validation experience, and equipped with advanced simulation systems, we can rapidly create prototypes and conduct full-scale verification. We are committed to continuous optimization and adjustments to meet target requirements. No matter your needs, we are fully dedicated to undertaking the development and collaboration of various low-noise, high-airflow, high-efficiency, and long-lifespan fans.

Fluid dynamics simulation software empowers engineers to make smarter decisions more efficiently.

Prototype development, testing and iteration of prototypes, functional testing, and validation.

used to evaluate and optimize the performance, efficiency, and aerodynamic characteristics of fans.

R&D equipment

R&D equipment

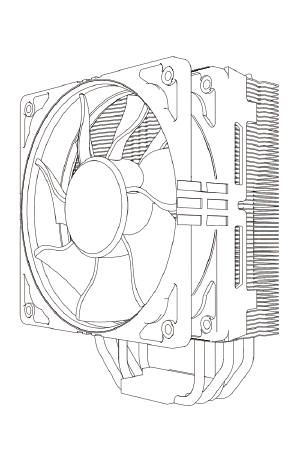

The noise testing room is used to accurately measure the noise levels of fans, helping to optimize designs, compare products, and improve performance. This process enhances user experience and ensures

Our injection molding machines offer enhanced flexibility and control, allowing quick adaptation to market changes and customer demands. This shortens the time from order to delivery, reduces producti

The wind tunnel testing system is essential for fan design and testing. By simulating real-world environments, it evaluates performance, optimizes designs for greater efficiency, and reduces noise. Ad

CFD fluid simulation is used to analyze and optimize airflow characteristics in a digital environment, focusing on aspects such as wind speed, pressure distribution, and turbulence intensity. This pro

Our automated equipment includes SMT high-precision component inspection, automatic winding machines, 3-in-1 systems, labeling, and visual inspection processes. These technologies ensure stable and re

Company