1.Market Research:

Identify target markets and customer needs.

Analyze competitor products or customer-provided samples to understand existing solutions and technologies in the market. Conduct a team review to assess project feasibility.

2.Requirement Definition:

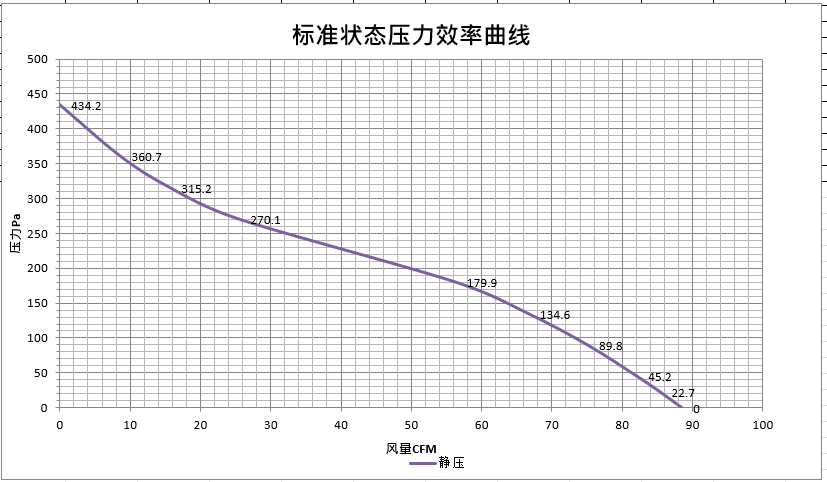

Determine the fan's performance requirements, such as airflow, noise levels, size, and durability.

Initially define the product specification sheet.

3.Concept Design:

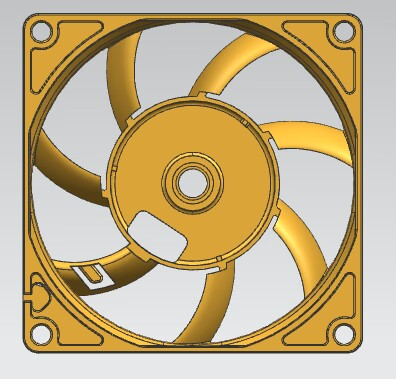

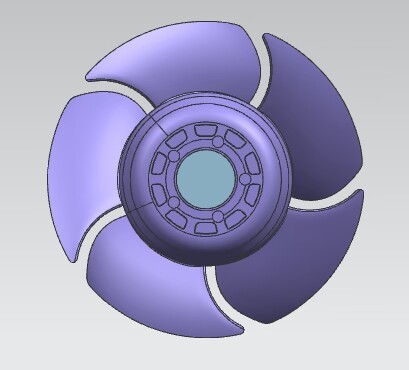

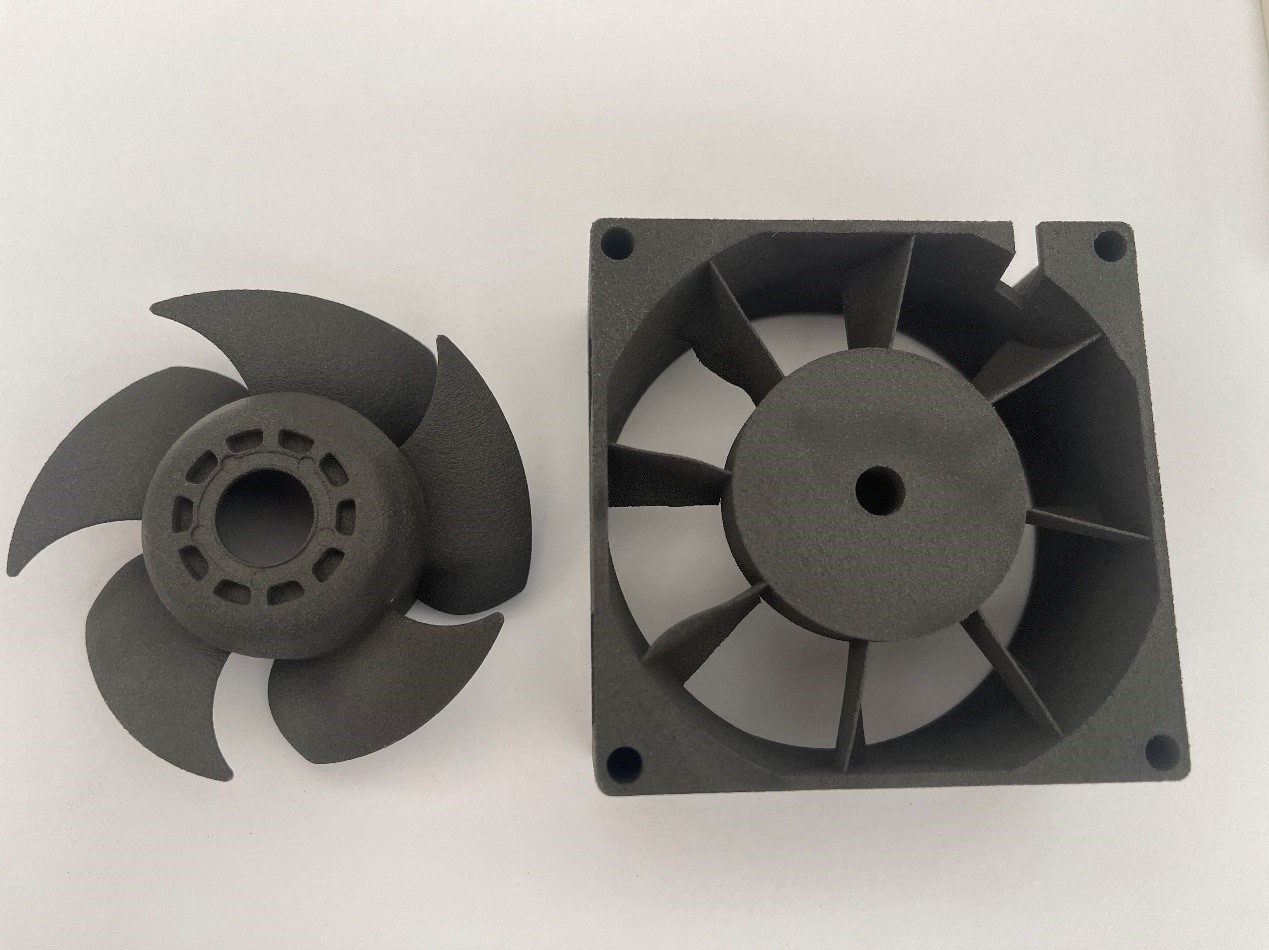

Create an initial design for the fan’s structure, shape, and materials.

|  |

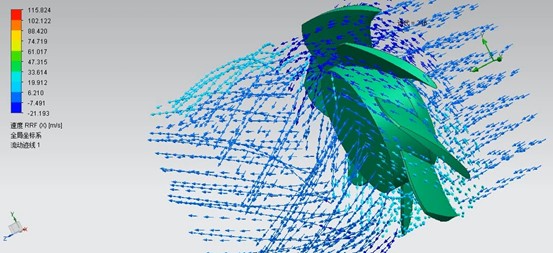

Use CAD software for model design and perform preliminary performance evaluations with simulation systems.

4.Prototyping and Testing:

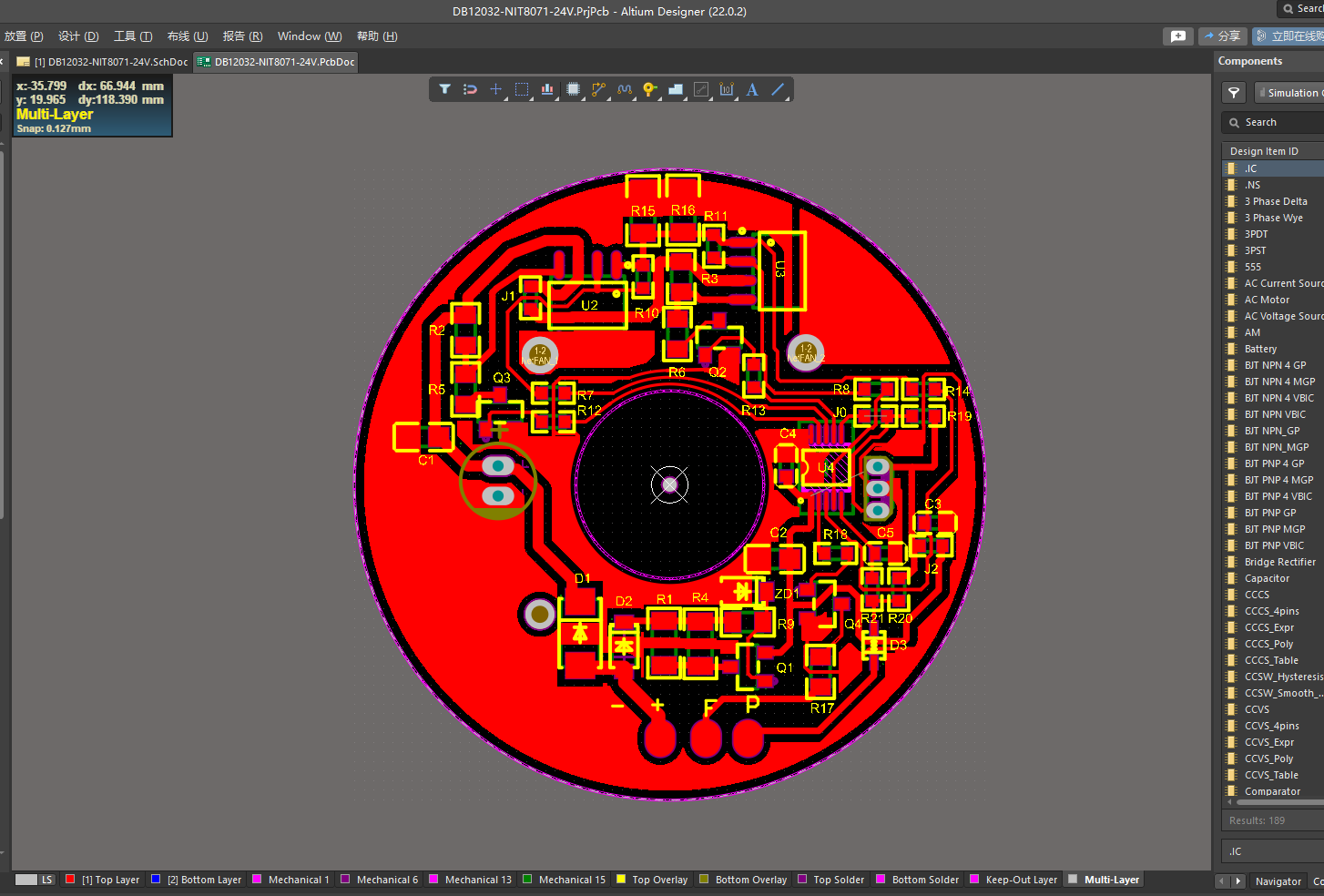

PDesign the PCB, select components, and choose functional options and certification materials.

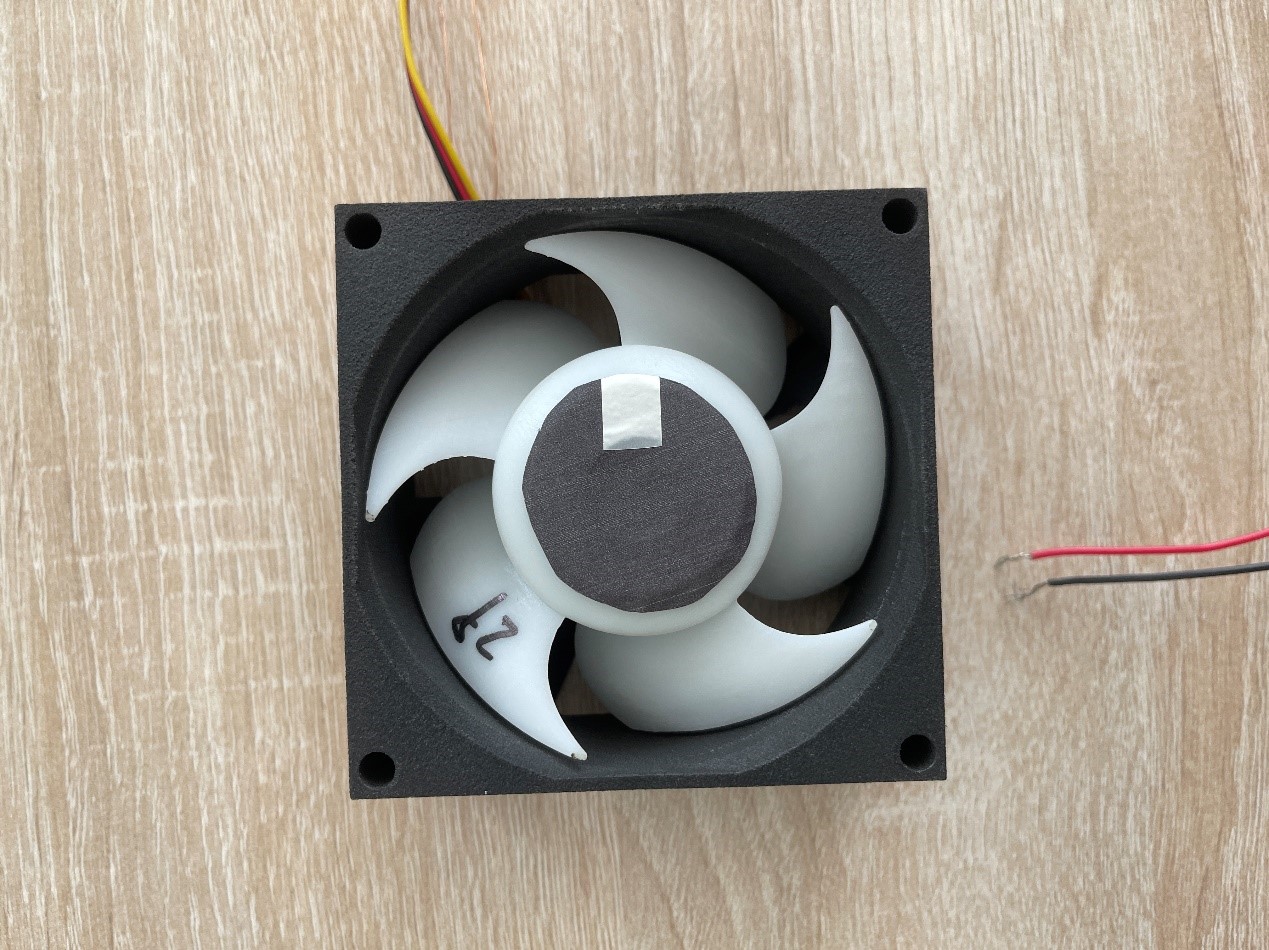

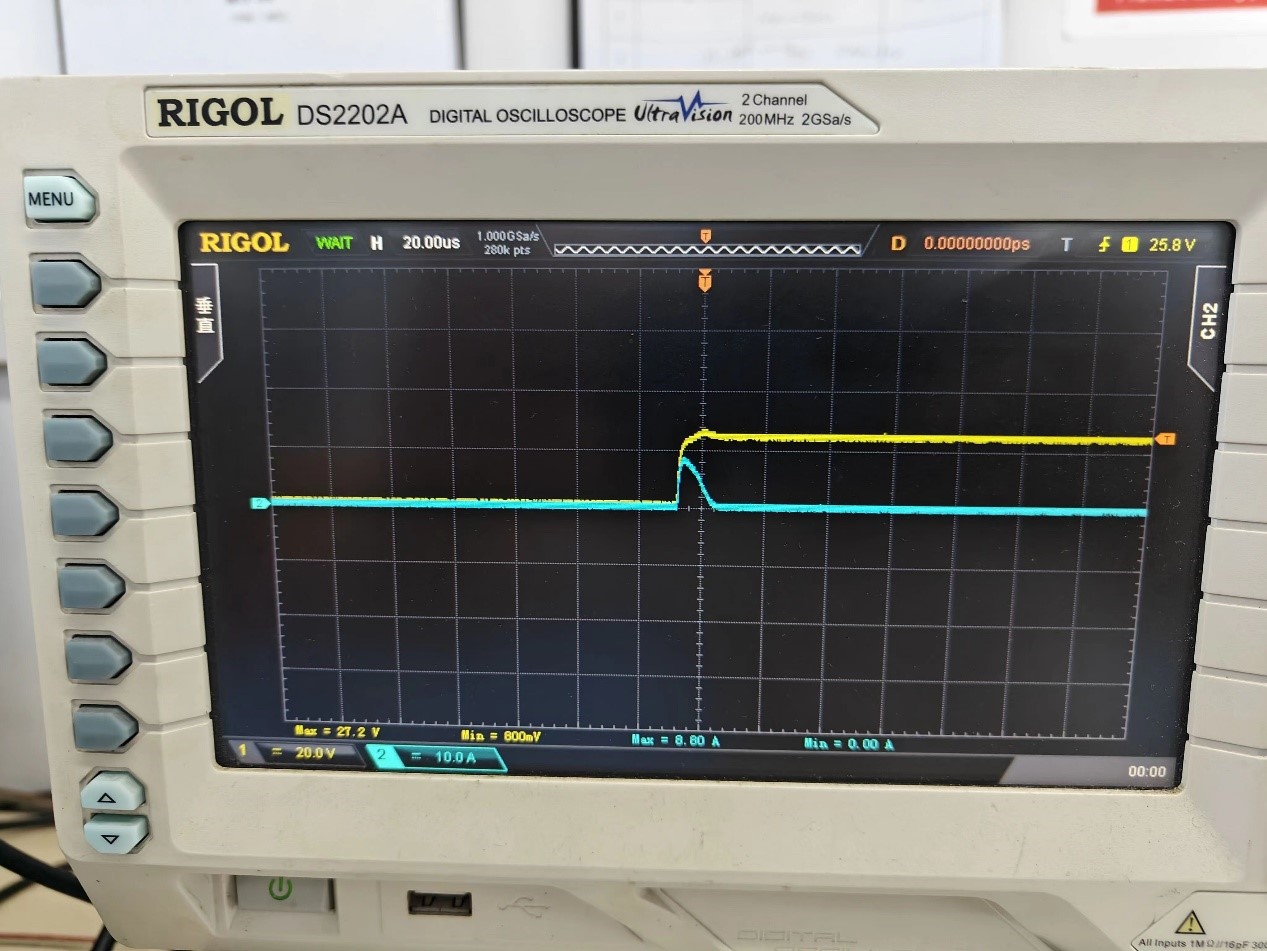

Build initial prototypes and conduct laboratory tests.

|  |

Tests include airflow efficiency, noise control, durability, and circuit performance testing.

|  |

5.Design Optimization:

Modify and optimize the design based on test results.

Multiple rounds of prototyping and testing may be needed to meet design standards.

6.System Integration Testing:

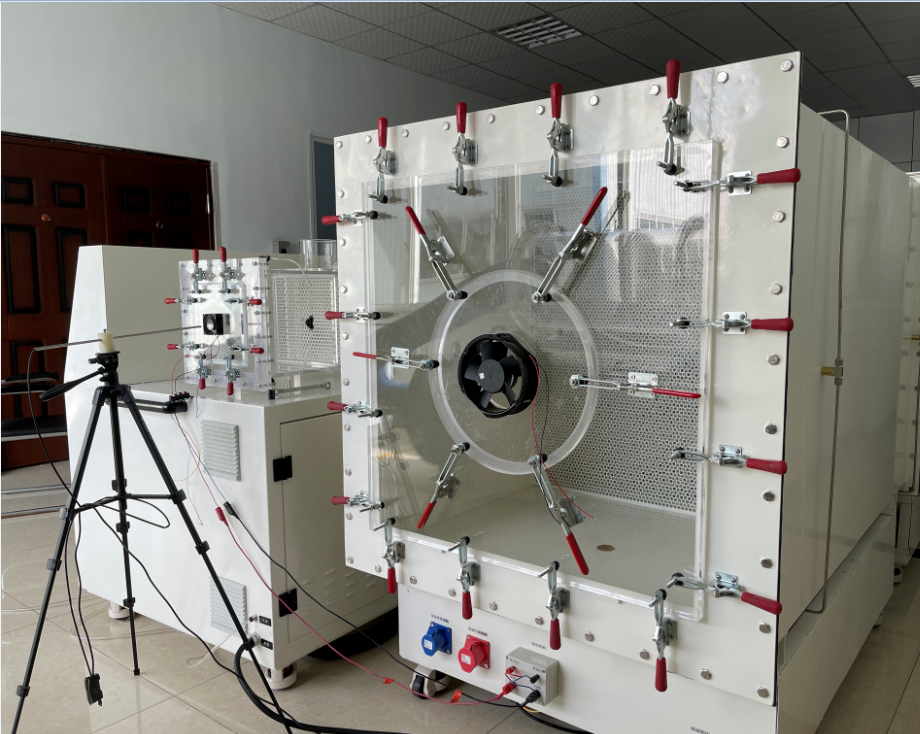

Integrate the fan into the target system (e.g., computers, cars) for system-level testing.

Confirm the fan’s performance in real-world environments.

7.Mass Production Preparation:

Define the production process, including material selection, manufacturing techniques, and quality control standards.

Prepare the production line and supply chain management.

8.Customer Feedback and Product Iteration:

Collect customer feedback and evaluate the product’s market performance.

Iterate and improve the product based on feedback.

By following these steps, the cooling fan development process, from concept to market, is carefully planned and executed to meet user needs and market standards.