With the widespread use of outdoor devices like charging stations, cooling systems face increasingly stringent environmental demands, particularly for waterproof performance. Typically installed outdoors, charging stations’ cooling fans endure rain exposure, challenging their reliability and lifespan. How, then, do waterproof and silent cooling fans achieve effective water resistance? Anpu Electric's high-power outdoor cooling fans incorporate waterproofing considerations from the initial stages of mold design, primarily through the following protective measures.

1. Sealed Coil Protection

In standard motors, coils are typically wound directly onto silicon steel sheets, leaving them susceptible to moisture, especially in humid or rainy conditions. For outdoor applications like charging stations, Anpu Electric’s design team focuses on waterproof sealing to protect the coils from rain interference. Specifically, the motor coils are fully encased within a black insulated cover, preventing water from contacting the coils and eliminating potential water seepage risks. This design gives the motor component an exceptionally high waterproof capability.

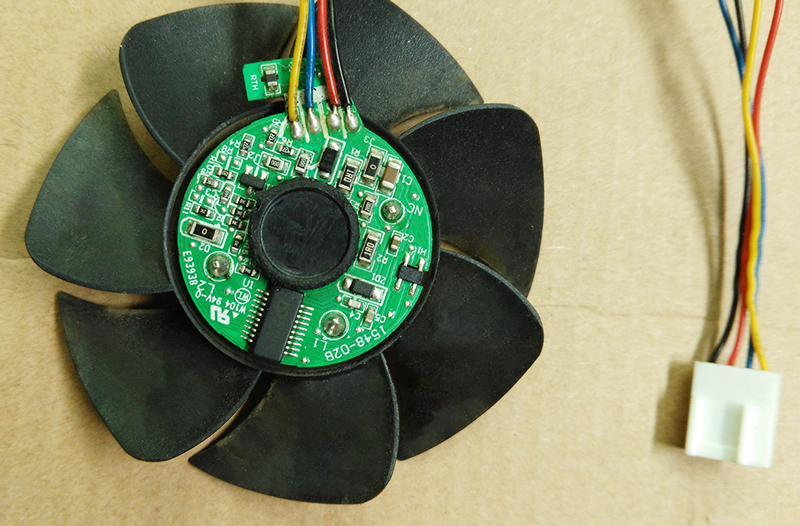

2. Waterproof Coating on the Control Board (PCB)

The motor’s control board (PCB) also requires critical protection. Typically, exposed PCBs are vulnerable to moisture, which can lead to oxidation and short circuits. To address this, Anpu Electric applies a specialized waterproof coating to the PCB, ensuring resilience against harsh outdoor conditions. Even if the PCB encounters water, this coating prevents short-circuiting and oxidation, guaranteeing stable fan operation. Through these two waterproofing measures, Anpu Electric’s cooling fans achieve an IPX7 waterproof rating, enabling them to operate reliably even in submerged conditions and significantly enhancing durability in outdoor environments.

Silent Fan Selection and Optimization Methods

For many indoor and outdoor applications, low noise is essential. Users desire cooling fans that operate quietly without compromising cooling performance. To meet the market's demand for low noise, Anpu Electric provides multiple silent cooling fan optimization solutions.

1. Increasing Airflow and Pressure to Lower Speed

When the fan size is fixed, we recommend selecting fans with high airflow and high static pressure. These fans can deliver the same cooling performance at a lower speed, reducing air friction and thus lowering noise. This method is effective for size-constrained devices, significantly enhancing silent operation.

2. Increasing Size to Lower Speed

If the fan size is flexible, opting for a larger fan can provide high airflow at a lower speed, achieving the same cooling performance while substantially reducing operational noise.

3. Reducing Speed to Minimize Noise

For applications with lower cooling demands, reducing the fan's existing speed is a simple yet effective approach, especially suitable for devices with limited space and budget.

4. Selecting High-Efficiency Motors and Optimizing Blade Design

Anpu Electric also offers specially designed silent fans that use high-efficiency motors and optimized blade designs. These fans maintain relatively low noise levels even at higher speeds. High-efficiency motors consume less power, produce less friction, and the optimized blade design reduces airflow interference, further lowering operational noise.

Advantages of Ruiapple Electric’s Waterproof and Silent Cooling Fans

Ruiapple Electric’s waterproof and silent cooling fans excel in both cooling performance and noise reduction through unique sealing and speed-control technologies. With an IPX7 waterproof rating and excellent silent operation, Ruiapple provides reliable and durable cooling solutions tailored for outdoor equipment like charging stations, meeting the market’s demand for efficiency and low noise.