The PWM (Pulse Width Modulation) speed control line plays a crucial role in modern cooling fans. Not only does PWM control help optimize cooling efficiency, but it also significantly reduces fan noise, making fans more adaptable to different applications. This article will explore how a fan performs without a connected PWM speed control line, its potential impacts, and analyze the core role of the PWM line.

What is the PWM Speed Control Line?

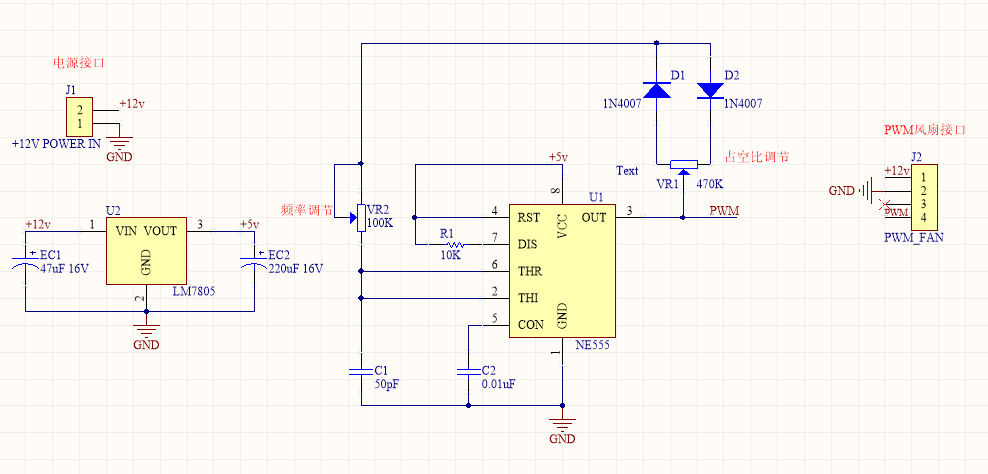

The PWM speed control line is a control signal wire that adjusts fan speed by modifying the duty cycle of the signal. The duty cycle represents the ratio of “on” time to “off” time. For example, a 50% duty cycle means the signal is “on” half of the time and “off” the other half, resulting in the fan running at half speed. The PWM speed control line not only affects fan speed but also plays a vital role in efficient cooling and energy saving.

Can a Fan Operate Without the PWM Speed Control Line?

Without a connected PWM speed control line, a fan can still operate but will run at its default speed, usually preset to the maximum level. This means the fan will run at full power and won’t adjust its speed based on temperature or demand changes. As a result, fans without a PWM line will remain at a fixed speed, which may lead to less-than-ideal efficiency and noise control.

Functions of the PWM Speed Control Line in Fan Systems

In fan systems, the PWM speed control line serves several core functions:

Precise Speed Control: By varying the duty cycle of the PWM signal, users can precisely adjust fan speed according to real needs. This feature is especially important in applications that require dynamic thermal management, such as CPU cooling or electronic device heat dissipation.

Energy Efficiency: With the PWM line connected, fan speed can synchronize with temperature changes. When device temperatures are low, the fan slows down, conserving power and extending device life. When temperatures rise, the fan speeds up to quickly expel heat.

Noise Control: Without PWM control, fans running at high speeds for extended periods generate more noise. The PWM line allows for speed adjustments based on actual cooling needs, reducing unnecessary noise and enhancing user experience.

Fault Warning and Protection: In some high-end devices, the PWM line also provides feedback on fan status, such as temperature and speed. This allows the system to monitor fan performance and issue fault warnings, helping prevent overheating or damage.

Potential Risks of Not Connecting the PWM Line

In certain applications, leaving the PWM line unconnected may lead to the following issues:

Increased Fan Noise: Without the PWM line, the fan typically runs at its default maximum speed, generating higher noise, especially when high speed isn’t necessary.

Excessive Power Consumption: Without PWM control, the fan continuously runs at high speeds, leading to unnecessary power usage and reduced overall energy efficiency.

Increased Risk of Overheating: In applications requiring dynamic speed adjustments, the lack of PWM control might prevent the fan from accelerating quickly in response to rising temperatures, thereby increasing the risk of overheating.

Importance of the PWM Speed Control Line

The PWM speed control line is essential in cooling fan operation. It not only ensures that fan speed aligns with actual cooling needs but also provides a high-efficiency, energy-saving, and low-noise solution through precise speed control. For devices operating in complex environments or with frequent temperature changes, PWM control is especially critical. To achieve optimal fan performance, users should ensure proper connection of the PWM line and verify that the controller or motherboard supports PWM. If you’re unsure about setup, we recommend contacting a professional cooling fan manufacturer—Ruiapple Electric—to ensure a stable and reliable experience.