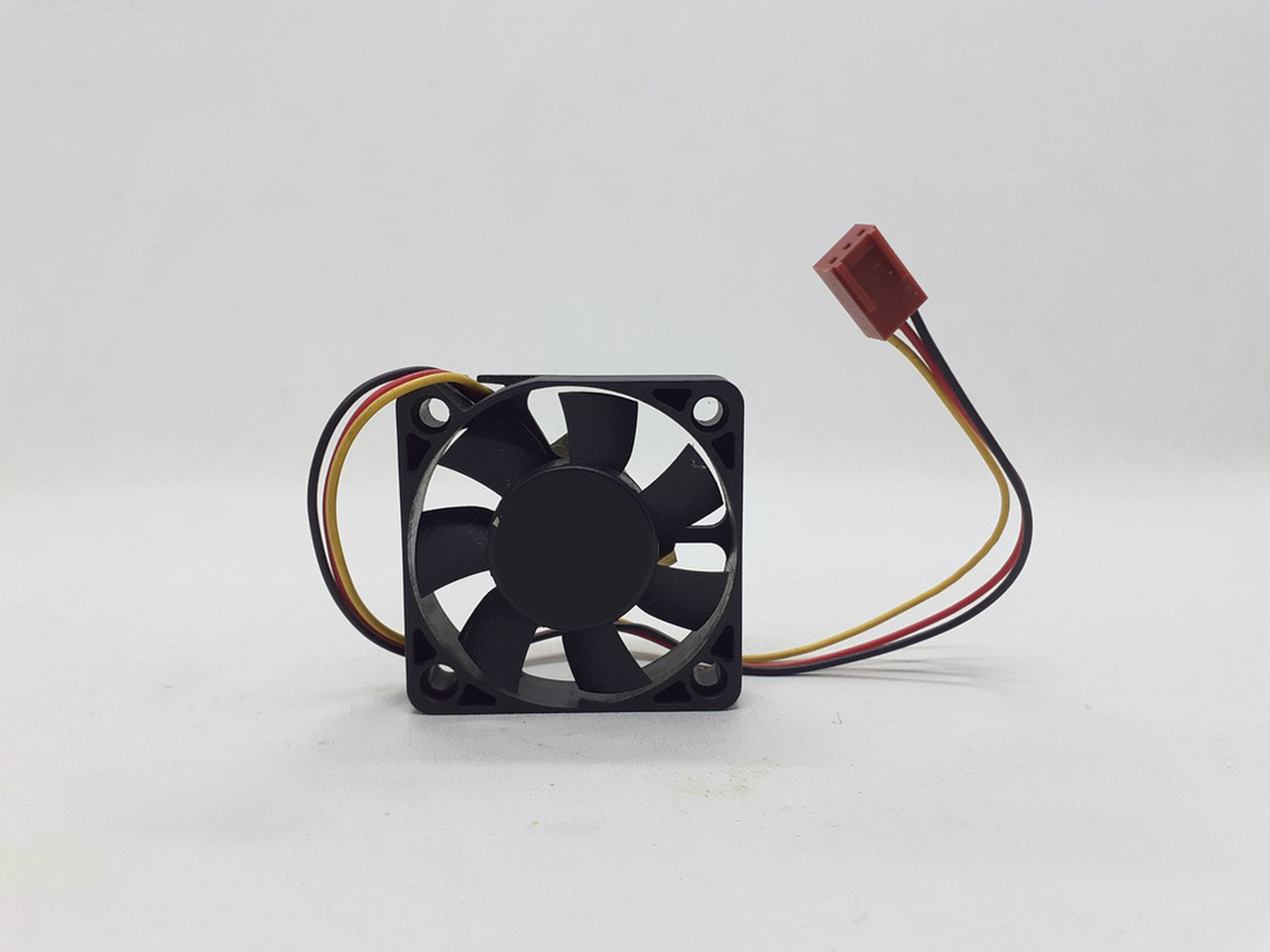

Cooling fans, as critical components in electronic devices, directly influence the stability and lifespan of the equipment. One interesting and notable design feature of these fans is that they almost always have an odd number of blades, such as 5, 7, or 9. This design is not coincidental but is based on principles of physics, aerodynamics, and engineering practices to ensure the fan’s efficiency and reliability.

1. Avoiding Resonance

Resonance occurs when an external driving force’s frequency matches a system’s natural frequency, causing strong vibrations. For cooling fans, if the blades are arranged symmetrically in an even-numbered configuration, resonance can occur at certain rotational speeds. This resonance can lead to:

- Increased noise: Resonance amplifies vibrations, resulting in louder noise, which negatively impacts user experience.

- Component damage: Prolonged resonance can cause early wear and failure of fan blades, bearings, and other components.

In contrast, the odd-numbered blade design disrupts symmetry and prevents resonance, thereby improving the fan's stability and reliability.

2. Optimizing Dynamic Balance

Dynamic balance is crucial for the performance of high-speed rotating cooling fans. Poor dynamic balance causes vibration, which can reduce cooling efficiency and shorten the fan's lifespan. The odd-numbered blade design helps optimize mass distribution and airflow stability, leading to smoother operation:

- Manufacturing advantage: It’s easier to achieve ideal dynamic balance through fine-tuning during production with odd-numbered blades.

- Stable operation: Improved dynamic balance reduces vibration-induced noise and energy loss.

3. Enhancing Aerodynamic Performance

The primary function of a cooling fan is to dissipate heat from the equipment by moving air. The quality and flow pattern of the airflow are directly influenced by the blade design. Odd-numbered blades offer significant advantages in this area:

- Reduced airflow interference: The asymmetric arrangement of odd-numbered blades reduces airflow collisions between blades and minimizes vortex formation.

- Improved cooling efficiency: More uniform airflow distribution allows heat to be expelled more efficiently, maintaining stable operating temperatures.

4. Cost and Design Trade-offs

While even-numbered blades can meet specific requirements in some applications, their production and adjustment process is generally more complex. The symmetry of even-numbered blades increases the difficulty of dynamic balance calibration, often requiring additional design and fine-tuning. Odd-numbered blades, however, have become a standardized solution in the cooling fan industry:

- Reduced production complexity: Odd-numbered blades lower the cost of high-precision calibration, improving manufacturing efficiency.

- Better market competitiveness: By balancing performance stability and cost control, odd-numbered blades have become the industry standard.

5. Riapple Electric’s Innovation and Practice

With 24 years of experience in manufacturing cooling fans, Ruiapple Electric continues to optimize the research and application of odd-numbered blades. Our products are designed not only to avoid resonance, optimize dynamic balance, and improve cooling efficiency but also to meet diverse market demands through technological innovation and material selection. Ruiapple Electric's cooling fans lead the industry in efficiency, energy savings, and environmental sustainability, making them a reliable choice for both electronic devices and industrial applications.

This translation maintains a professional tone, with clear and concise explanations, and emphasizes the technical details for customer understanding.