With advancements in technology, the demand for cooling fans has increased, and high-temperature-resistant DC fans have become essential in many industrial and automotive applications. Standard cooling fans typically operate in a temperature range of -10°C to 70°C. However, in specific applications, especially in high-temperature environments, standard fans are not suitable, and specialized high-temperature fans are required. So, what is the maximum temperature that a high-temperature fan can withstand? This article explores the design principles and the maximum temperature tolerance of high-temperature fans.

- Temperature Range of High-Temperature FansConventional cooling fans operate within a range of -10°C to 70°C. High-temperature DC fans, however, are designed to function in more extreme temperature environments, typically enduring temperatures of 100°C to 150°C. In certain specialized applications such as automotive electronics, LED lighting, and industrial equipment, high-temperature fans can even operate in environments exceeding 200°C.

- Design Key Points: Core Technologies for High-Temperature PerformanceTo ensure fans can operate stably in high-temperature environments, every component needs to be specifically designed to handle the challenges posed by temperature fluctuations. Key design factors include:

- Circuit DesignThe fan's circuit must use high-temperature-resistant drive ICs and electronic components (e.g., resistors, capacitors, diodes), with reliable circuit design. In automotive applications, the circuit must meet automotive electronic standards (such as AEC-Q100) to ensure stability in high temperatures and complex environments, including vibration.

- Magnetic Circuit DesignThe design of the magnetic circuit is crucial to ensure long-term stable operation in high temperatures. The choice of permanent magnets is critical; traditional rubber magnets and neodymium magnets are unsuitable for high-temperature environments. Sintered ferrite materials maintain stable magnetism at high temperatures, and the excitation coil needs to be made of high-temperature-resistant winding wire to prevent coil burnout or magnetic degradation due to high heat.

- Bearing DesignBearings are vital for the long-term operation of fans. For high-temperature fans, high-temperature-resistant double ball bearings are essential. Standard bearings have a shorter lifespan under high heat, as lubricant oils may vaporize, leading to failure. Although double ball bearings produce more noise, oil-impregnated bearings are ideal in high-temperature environments, offering better stability and quieter operation for noise-sensitive applications.

- Motor DesignHigh-temperature DC fans typically use coreless, hollow coil motor designs, which effectively reduce motor temperature rise, improving overall fan efficiency and reliability. An efficient motor reduces energy consumption, lowers internal temperature rise, and enhances stability in high-temperature environments.

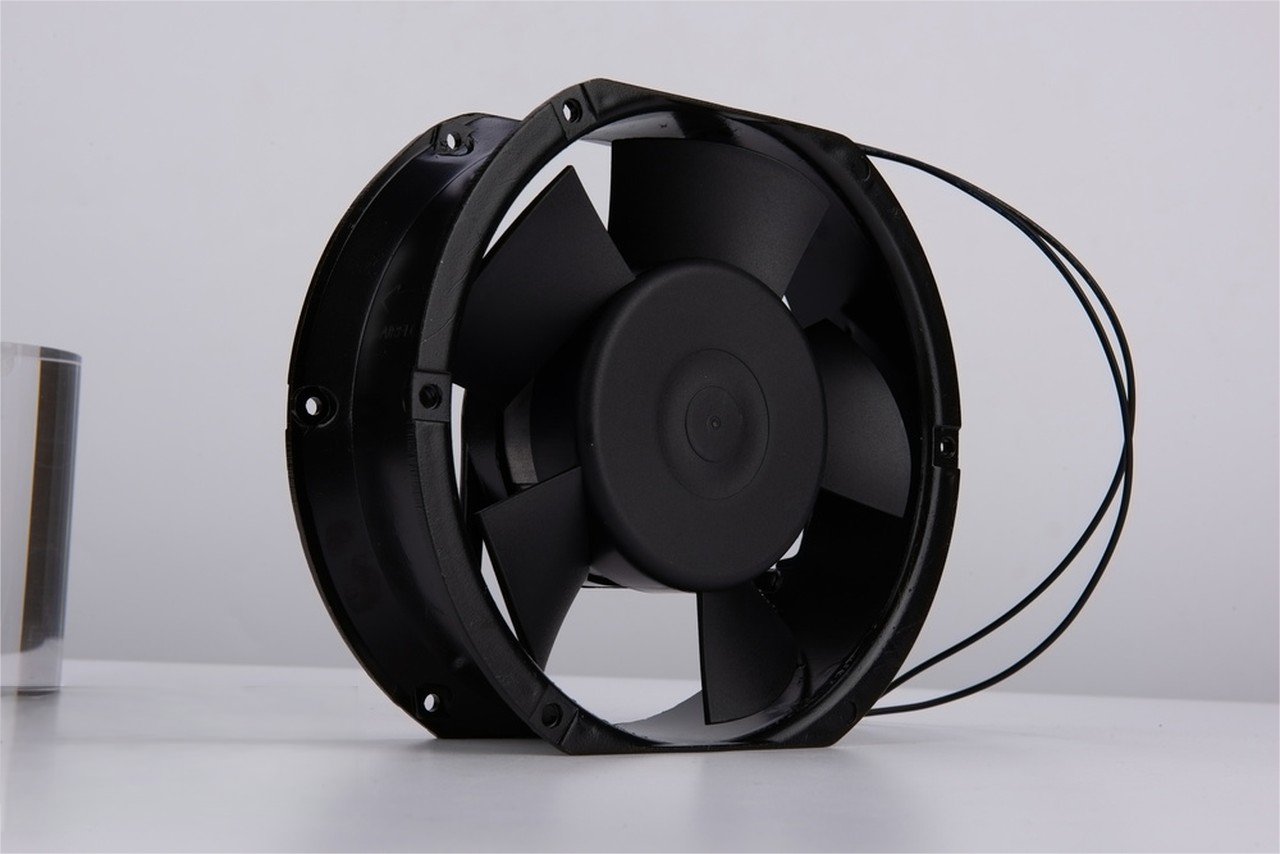

- Material SelectionHigh-temperature environments impose strict requirements on the fan's casing, blades, and wiring. Typically, high-temperature fans use materials such as PPS or PBT plastics for the casing, while blades are made of materials with high thermal stability. Additionally, wires and adhesives must be chosen for their high-temperature resistance to prevent deformation, aging, or detachment in extreme heat.

Real-World Applications and Temperature Endurance

- Automotive ElectronicsIn automotive environments, fans must handle high temperatures, humidity, and vibration. In engine compartments and battery management systems (BMS), high-temperature fans must withstand temperatures of up to 125°C or higher. Particularly in electric vehicles, fans must reliably operate in the 80°C to 125°C range for continuous, stable performance.

- LED LightingLED lighting systems require fans to effectively dissipate heat and prevent overheating damage. In high-temperature operating conditions, fans need to endure temperatures ranging from 100°C to 150°C. This is especially critical in high-power LED applications, where the fan's ability to handle heat is vital.

- Industrial Equipment and ServersCooling fans for industrial equipment and servers often need to function at higher temperatures. For specific industrial equipment, high-temperature fans can operate in environments reaching 85°C or even higher, ensuring long-term stability of the equipment.

- High-Temperature Durability Testing and CertificationHigh-temperature fans must not only meet relevant standards but also undergo rigorous high-temperature durability testing to verify their stability and reliability under extreme conditions. Common tests include high-temperature cycling and high-temperature humidity tests. After passing these tests, fans can ensure reliable performance without degradation or failure due to excessive heat.

- Ruiapple Electric's High-Temperature Fan SolutionsRuiapple Electric specializes in the research, development, and manufacturing of high-temperature fans, which are widely used in automotive, industrial, and LED lighting applications. Our high-temperature DC fans operate stably in extreme environments ranging from -40°C to 150°C, ensuring effective heat dissipation and operational safety. Our products are certified by UL, CE, RoHS, and other international standards, offering reliable quality and outstanding performance—making them the ideal choice for applications in high-temperature environments.

High-temperature environments demand higher standards in fan design, covering components such as circuits, magnetic circuits, bearings, motors, and materials. Only through meticulous design and testing can high-temperature fans maintain stability and reliability under extreme conditions. With years of experience in this field, Ruiapple Electric is dedicated to providing efficient and reliable high-temperature cooling solutions for our customers.