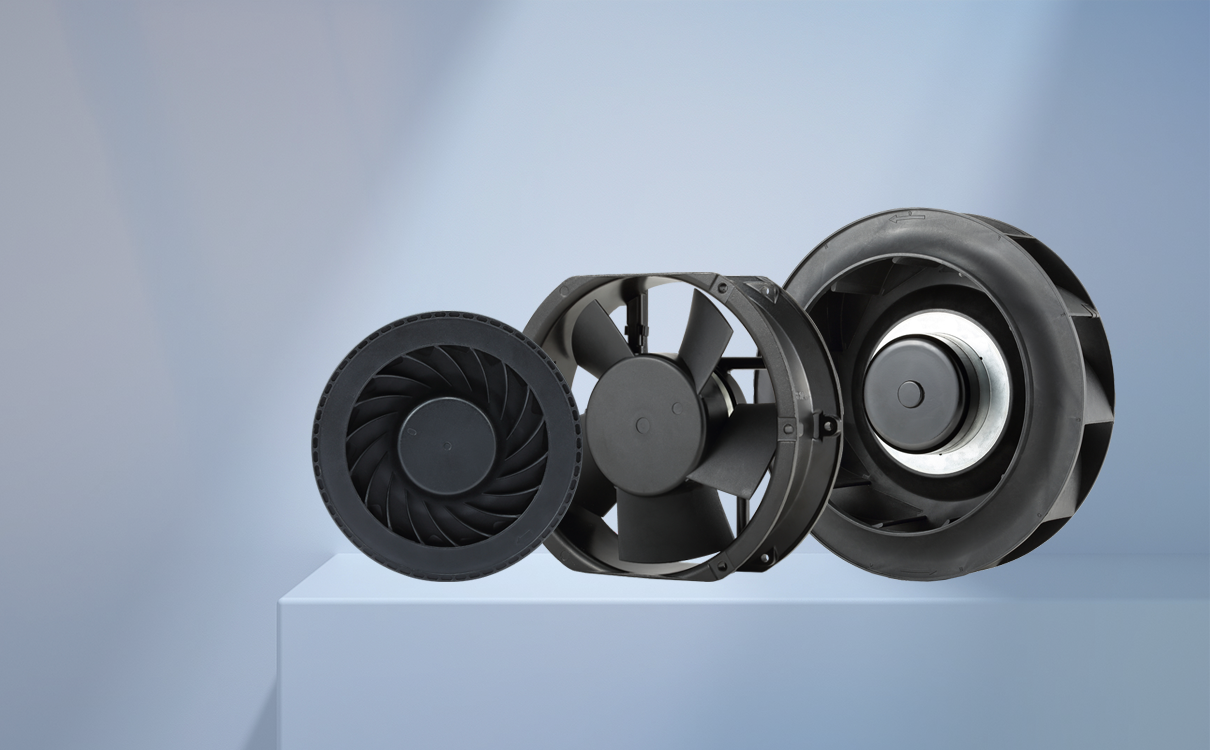

Both backward-curved centrifugal fans and cooling fans are essential devices for airflow management and heat dissipation. However, they differ significantly in terms of operating principles, design structures, and application scenarios. The backward-curved centrifugal fan is a specialized type of cooling fan, but its unique design and powerful cooling capabilities give it an undeniable advantage in certain applications. This article will analyze the differences between the backward-curved centrifugal fan and the cooling fan to help users understand their characteristics and suitable applications.

Operating Principle and Design Structure

A backward-curved centrifugal fan, often referred to as a centrifugal backward-curved fan, operates on the principle of centrifugal force. It uses a motor to drive a rotor that spins at high speed. The blades of the rotor accelerate the air, increasing its kinetic energy, which is then converted into pressure energy. Specifically, when the air enters the fan, the blades increase the momentum of the gas, and under the influence of centrifugal force, the air is expelled through the volute casing, where kinetic energy is transformed into pressure and the gas is pushed out. The main advantage of the backward-curved centrifugal fan is its highly efficient heat dissipation and powerful airflow, allowing it to provide a substantial volume of air in a compact space and effectively reduce equipment temperature in a short time.

In contrast, traditional cooling fans rely on axial flow, where a motor drives blades that directly push air onto heat dissipation surfaces. Cooling fans typically operate at lower speeds and have a simpler design, making them suitable for applications that require low noise and compact spaces.

Advantages and Disadvantages Comparison

Advantages of Backward-Curved Centrifugal Fans:

- High airflow, strong cooling capability: The backward-curved centrifugal fan can deliver powerful airflow in a small space, making it ideal for high-power electronic equipment, automotive engines, and other devices that require efficient heat dissipation.

- Compact design: Due to the centrifugal design, the fan can provide efficient cooling in space-constrained environments, making it widely used in the cooling systems of machinery and electronic devices.

Disadvantages of Backward-Curved Centrifugal Fans:

- High speed, high noise: The fan requires high speeds (sometimes over 3000 RPM), which can generate significant noise, especially in smaller spaces. Noise can be a problem in applications where quiet operation is necessary.

- Safety risks: High speeds increase the airflow intake, and without proper safety measures, there may be risks to human health. The fan's intake design usually lacks extensive barriers, so special attention is needed for safety precautions.

Advantages of Cooling Fans:

- Low noise, low speed: Cooling fans typically operate at lower speeds and generate less noise, making them suitable for noise-sensitive environments like home appliances and medical devices.

- High safety: Due to their lower speeds and simpler design, cooling fans are generally safer and less likely to cause harm to humans.

Disadvantages of Cooling Fans:

- Weaker cooling capacity: Compared to backward-curved centrifugal fans, cooling fans provide lower airflow and weaker cooling performance, especially in high-power devices.

- Larger space requirement: To ensure proper airflow, cooling fans typically require more space, which may not be suitable for compact devices.

Application Fields Comparison

The application fields of backward-curved centrifugal fans and cooling fans differ significantly. Choosing the appropriate fan type is critical to ensuring optimal performance and safety for equipment.

Applications of Backward-Curved Centrifugal Fans: These fans are primarily used in environments with high heat dissipation demands and where noise is less of a concern. For example, they are commonly found in automotive engine cooling systems, industrial machinery, and high-performance electronic devices. In these environments, the high airflow provided by the fan helps prevent overheating and equipment damage. Since noise is usually not a primary concern in such settings, the high speed and noise of the backward-curved centrifugal fan are more acceptable.

Applications of Cooling Fans: Cooling fans are widely used in home appliances, medical equipment, computers, televisions, and household air conditioning units. These devices typically need to maintain low noise levels, so cooling fans are preferred for their quiet operation, high safety, and low power consumption. Although the cooling performance may be slightly lower, the low noise and compact design are more critical in these applications.

Conclusion

Ruiapple Electric, as a professional manufacturer of cooling fans, offers both backward-curved centrifugal fans and traditional cooling fans that combine high efficiency, low noise, and excellent safety design. Our fans are suitable for a variety of application scenarios based on specific needs. With years of industry experience and advanced technology, we are committed to providing customized cooling solutions that ensure efficient heat dissipation while meeting safety and noise control requirements.