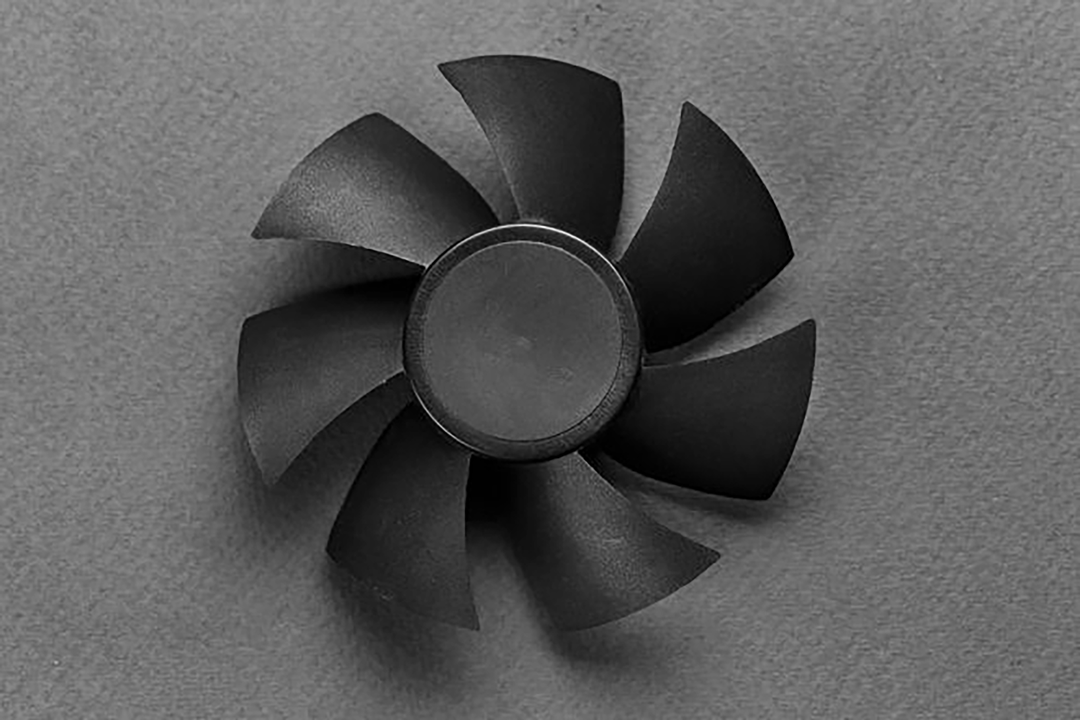

DC fans are critical components widely used in electronic devices and cooling systems. By converting electrical energy into mechanical energy through DC voltage and electromagnetic induction, these fans drive the blades to rotate, generating airflow and enabling heat dissipation. While the importance of the fan casing and motor is commonly understood, the fan blades, as one of the core components, play a vital role in the performance of DC fans. This article explores the key functions of fan blades in DC fans and analyzes how various design parameters affect fan performance.

1. Blade Curvature and Its Impact on Airflow and Pressure

Blade curvature is a key factor affecting the performance of DC fans. Within a certain range, the greater the blade curvature, the higher the kinetic energy of the air at a given rotational speed, which enhances both airflow and air pressure. Airflow refers to the volume of air moved per unit of time, while air pressure refers to the resistance encountered by the air during flow. A greater blade curvature results in stronger airflow, enabling the fan to overcome higher internal air resistance.

However, increasing the blade curvature also increases the air resistance, requiring the motor to provide more torque to drive the blades. The motor's output power and torque must match the blade curvature changes, or the motor may become overloaded, affecting fan stability and lifespan. Therefore, fan design must balance blade curvature, airflow, and air pressure to ensure sufficient airflow without overloading the motor.

2. Motor Diameter and Blind Spots

The diameter of the motor significantly impacts fan performance. Due to the presence of the motor and bearings, a "blind spot" is created around the fan's main shaft. This refers to areas where airflow is obstructed due to physical limitations of the motor and bearings. The absence of airflow in these regions affects the overall airflow and pressure of the fan.

The size of the motor's main shaft diameter directly determines the size of this blind spot. High-power motors typically require larger stator winding coils, occupying more space. When increasing the height of the fan is not possible, designers often increase the motor's lateral area. This design can impact the overall airflow distribution, especially in the center of the fan, where airflow tends to be weaker. When selecting a fan, it is crucial to consider the motor diameter's influence on airflow distribution.

3. Blade Curvature and Airflow Concentration

In addition to the blade curvature, the degree of blade bending (or arc) is another critical factor influencing fan performance. The blade's arc is noticeable in the top-down plane, where the blades do not extend radially but are slightly curved in the direction of rotation. This curvature effectively concentrates the airflow, improving both the fan's airflow distance and pressure.

If the blades extend radially without any curvature, the airflow driven by rotation tends to scatter at the outlet, resulting in uneven airflow distribution, shorter air delivery distances, and a lack of concentrated force. By incorporating an appropriate blade curvature, the airflow can be concentrated directly in front of the outlet, forming a columnar airflow that increases the airflow distance and improves air pressure, allowing the fan to operate efficiently even in high-resistance environments.

4. Blade Spacing and Airflow Stability

The spacing between fan blades plays a crucial role in airflow stability and fan efficiency. If the gap between blades is too small, airflow disturbances can occur, leading to uneven airflow and increased friction on the blade surfaces. This not only reduces fan efficiency but can also cause motor overload, increasing energy consumption. Conversely, excessive spacing between blades may lead to increased pressure loss in the airflow, reducing air pressure and compromising the fan’s cooling performance.

Optimal blade spacing should ensure smooth and stable airflow, minimizing unnecessary friction and pressure losses to enhance overall fan efficiency. The spacing should be carefully adjusted based on the fan's operating environment, airflow requirements, and working conditions to achieve the best airflow distribution and performance.

5. Blade Material and Durability

The material of the fan blades is another significant factor in determining the performance of DC fans. High-quality materials ensure stability under heavy loads, extending the fan’s service life. Common materials for fan blades include plastics, aluminum alloys, and composite materials. Plastic blades are cost-effective but have relatively poor high-temperature resistance. Aluminum alloy blades offer good heat dissipation and durability, while composite materials combine light weight and high strength, making them suitable for high-performance fans.

Choosing the right blade material can significantly enhance the fan's operational stability and prevent performance degradation due to material aging. As a leading DC fan manufacturer, Ruiapple Electric is committed to providing high-performance, high-efficiency cooling solutions. Our fan products feature advanced blade designs and high-quality materials to ensure exceptional cooling performance in various applications. Through continuous innovation and design optimization, Ruiapple Electric fans meet industry demands for high air pressure, low noise, and high energy efficiency, delivering better user experiences and longer product lifecycles.