After prolonged use, cooling fans may experience slower speeds and increased noise. These issues often stem from insufficient lubrication in the fan bearings, leading to poor operation and increased friction. Proper lubrication not only resolves these problems but also extends the fan’s lifespan. Below is a detailed guide on how to lubricate a cooling fan, ensuring effective maintenance.

1. Determine the Need for Lubrication

Before proceeding, assess whether the cooling fan requires lubrication. Look for the following signs:

- Difficulty starting or failure to start.

- Noticeable friction noise during operation.

- Reduced airflow and weakened cooling performance.

A simple inspection can confirm whether lubrication is needed. For severe issues, consider consulting a professional manufacturer, such as Anpu Electric, for expert advice.

2. Prepare Tools and Lubricant

Gather the following tools before lubricating the fan:

- Small screwdriver or tweezers (to open the bearing cap).

- High-quality lubricant, such as silicone-based oil or specialized bearing oil (avoid thick or sticky oils).

- Tissue or cotton swabs (to clean excess grease or debris).

Using a high-grade lubricant reduces internal friction and prevents dust accumulation, improving the fan's efficiency.

3. Lubrication Steps

- Remove the LabelLocate the sticker at the fan’s center. Carefully peel it back to expose the bearing, but do not fully remove it to preserve the adhesive.

- Clean the BearingUse tissue or cotton swabs to remove dust and dirt from the bearing surface. If there is old grease, clean it with a small amount of isopropyl alcohol and let it dry.

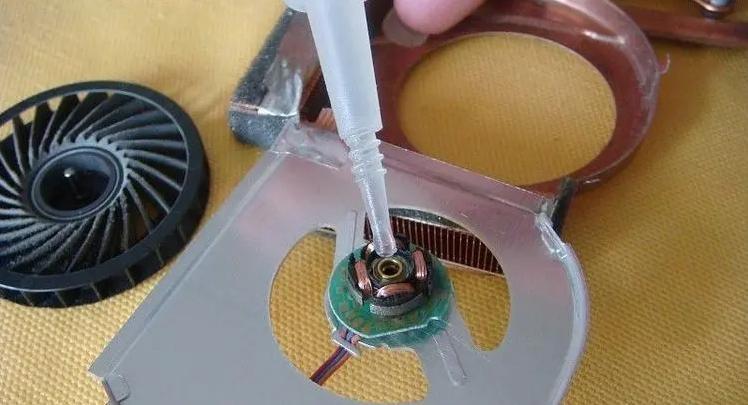

- Apply LubricantUse a screwdriver or tweezers to gently open the bearing cap (if present). Add 1–2 drops of lubricant onto the bearing. After each drop, manually spin the fan blades a few times to evenly distribute the lubricant inside. Avoid over-lubrication, as excess oil may spill and attract dust.

- Reassemble the Bearing and LabelReplace the bearing cap securely, then reposition the sticker. If the sticker loses adhesion, use a small amount of glue to fix it.

- Test the FanManually spin the fan blades to check for smooth operation. If the blades still feel stiff, add a small amount of lubricant and retest until the rotation is smooth.

4. Key Precautions

- Do not use unsuitable oils such as cooking oil or motor oil, as they can accelerate bearing wear or attract dust.

- Handle components gently to avoid damaging the sticker or bearing.

- Regularly inspect the fan’s lubrication, especially for fans in demanding environments. It is recommended to check every 6–12 months.

5. Importance of Regular Maintenance

Proper lubrication significantly prolongs the cooling fan’s service life while maintaining its efficiency. Regular maintenance is especially crucial for high-performance fans used in industrial equipment or servers. If you need further assistance or professional servicing, contact Ruiapple Electric. With 24 years of expertise, we provide high-quality products and comprehensive technical support.

By following these steps, you can easily lubricate your cooling fan, restore its efficient operation, and extend the equipment's lifespan.