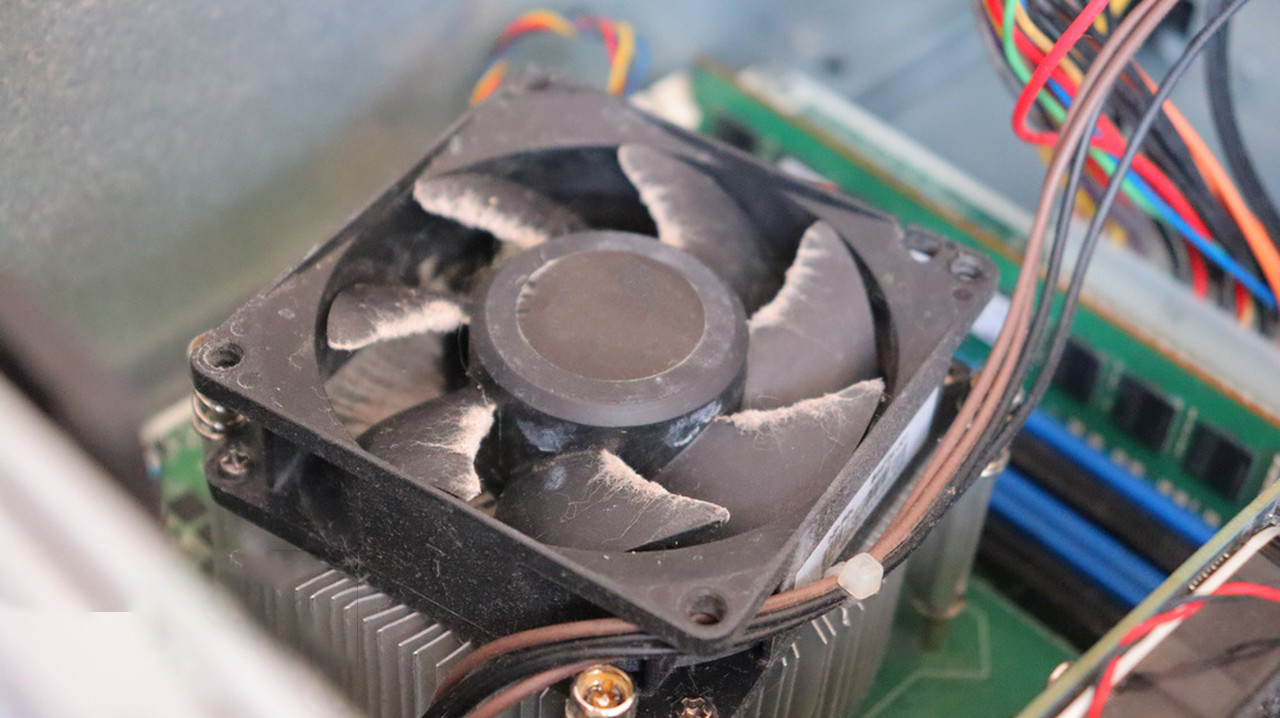

DC cooling fans are widely used in electronic devices, home appliances, and industrial equipment due to their high efficiency and reliability. However, over time, dust accumulation can negatively impact the fan's performance and lifespan. So, can DC cooling fans be dust-proof? Let’s explore this question by examining the structural design, material selection, and technological applications.

Dust-Proof Principle of DC Cooling Fans

The dust-proof capability of a DC cooling fan primarily depends on its structural design and sealing performance. For larger fans, such as the common 8CM and 9CM models, dust-proofing can be achieved by fully enclosing the motor and circuit in a dust cover. This design effectively prevents dust from entering critical components like bearings, coils, and PCBs, thereby reducing the risk of dust-related failures.

For smaller and thinner fans, such as those measuring 20x20x6mm or 30x30x7mm, the limited internal space makes it more challenging to incorporate a dust cover around the motor. However, by using advanced technology and high-performance materials, the dust-proof capability can still be enhanced within the restricted space.

Application of High-Performance Bearings in Dust-Proofing

To address the dust-proofing challenges in miniature fans, Anpu Electric recommends using ultra-thin dual-ball bearing fans. These bearings, crafted with high-precision technology from Japan, feature excellent sealing capabilities that effectively prevent dust from entering the bearing. Even when external components like coils and PCBs accumulate dust, the performance of the ball bearings remains stable. Compared to oil-filled bearings, dual-ball bearings offer significant advantages in dust resistance and lifespan, often lasting twice as long as oil-filled bearings.

Key Technologies Supporting Dust-Proof Fans

In addition to structural design and bearing performance, the manufacturing of dust-proof cooling fans also relies on several key technologies:

- Dust-Resistant Materials: The fan housing is made from abrasion-resistant, anti-static materials to reduce dust adhesion.

- Special Coatings: Dust-resistant coatings are applied to the surfaces of critical components inside the fan, further improving dust resistance.

- IP Protection Ratings: Fans are tested according to international IP protection standards (such as IP5X, IP6X) to ensure reliable performance in dusty environments.

- Optimized Airflow Design: Well-designed blades not only improve cooling efficiency but also reduce the retention of dust on the fan's surface.

How to Choose a Dust-Proof DC Cooling Fan

When selecting a dust-proof DC cooling fan, it’s essential to consider the application environment, fan specifications, and technical features. For high-density electronics or industrial settings, fans with an IP protection rating are recommended to ensure stable operation under harsh conditions. Anpu Electric’s dust-proof DC cooling fans, featuring dual-ball bearing design and fully enclosed motor technology, offer customers high-performance and long-lifetime solutions.

Core Brand Advantages

With 24 years of experience in manufacturing DC cooling fans, Ruiapple Electric not only focuses on continuous product performance optimization but also provides personalized solutions to meet various application requirements. Our dust-proof fans consistently lead the industry in reliability and protective performance, making them the preferred choice for many high-end devices. Through thoughtful design and technological innovation, DC cooling fans can fully achieve dust-proof functionality, extending the lifespan of equipment and providing customers with more efficient and reliable cooling solutions.

This translation ensures a clear, concise, and professional tone while conveying the technical details in an accessible way, focusing on key points that will be most relevant to customers.